THE STEPS AND THE SKIRTING BOARDS

- Home

- THE STEPS

THE STEPS

Steps made of ceramic granite are produced using the latest technology developed by Italian engineers and designers.

The manufacture of our steps differs:

- MODERN TECHNOLOGIES AND HIGH QUALITY

- Any formats’ variations and thickness of steps

- USING OF INNOVATIVE MATERIALS

THE SKIRTING BOARDS

The skirting boards made of ceramic granite are the most important element that completes the floor design, which is an essential detail of the future interior. The skirting board will become a harmonious and rational addition to any collection of floor tiles. A wide range, high operational and aesthetic qualities are ensured by the high accuracy, quality of execution and, of course, high strength characteristics of ceramic granite.

The skirting boards are made by cutting ceramic granite tiles, followed by rounding and polishing the upper edge. The finished face is decorated with a high-strength, light-resistant coating at the request of the customer.

Advantages of the ceramic granite skirting boards:

- Wide choice of colors and textures

- High strength, durability

- Resistance to moisture, contaminants, acids and alkalis, including household chemicals

- Simplisity of care

- Atmospheric persistence, resistance to fading

- Harmonious combination with any interior and exterior

The manufacture of steps and skirting boards is carried out on high-precision Italian equipment and technologies of leading companies.Heavy-duty ceramic granite tiles turn into an ideal step or skirting board, executed with filigree precision, because of new technologies and high qualification of the personnel.

Products are manufactured under controlled conditions, established The Quality Management System, functioning in accordance with the requirements of ISO 9001: 2015 and certificated by BV Certification.

THE SELECTION AND INSTALLATION OF STEPS

For the streets it is better to choose steps with a rough surface - they are not slippery and will not cause injury in the autumn-winter period. Straight slabs of ceramic granite are used for stairway, trapezoidal staircases are used for screw stairs. Trapezoidal plates are make to order. For premises and houses with low trafficability are suitable an aesthetic glazed ceramic granite. Stairs in buildings with intensive traffic (shop, office, etc.) are desirable to be faced with an unglazed, polished or mat ceramic granite. Such a coating will last for several decades.

Basic rules for the selection and installation of the steps

- The base under the steps must be strong and even, cleaned of dirt, dust, lime, grease, paint residues, rust.

- The surface of the steps is treated with a penetrating primer.

- Все неровности заделываются выравнивающимися растворами или шпаклевочными смесями и покрываются еще раз грунтом

- The basis for laying the steps and tiles can be all the generally accepted surfaces in construction: concrete, reinforced concrete, metal, old surfaces, etc. The surface of the steps is treated with a penetrating primer.

- The slabs of the treads are laid out on a step, being guided by the center. The tile must be placed symmetrically.

- An elastic or superelastic adhesives are used for the installation of ceramic granite steps in accordance with the operating conditions and manufacturer's recommendations. It is not allowed to have emptinesses without glue.

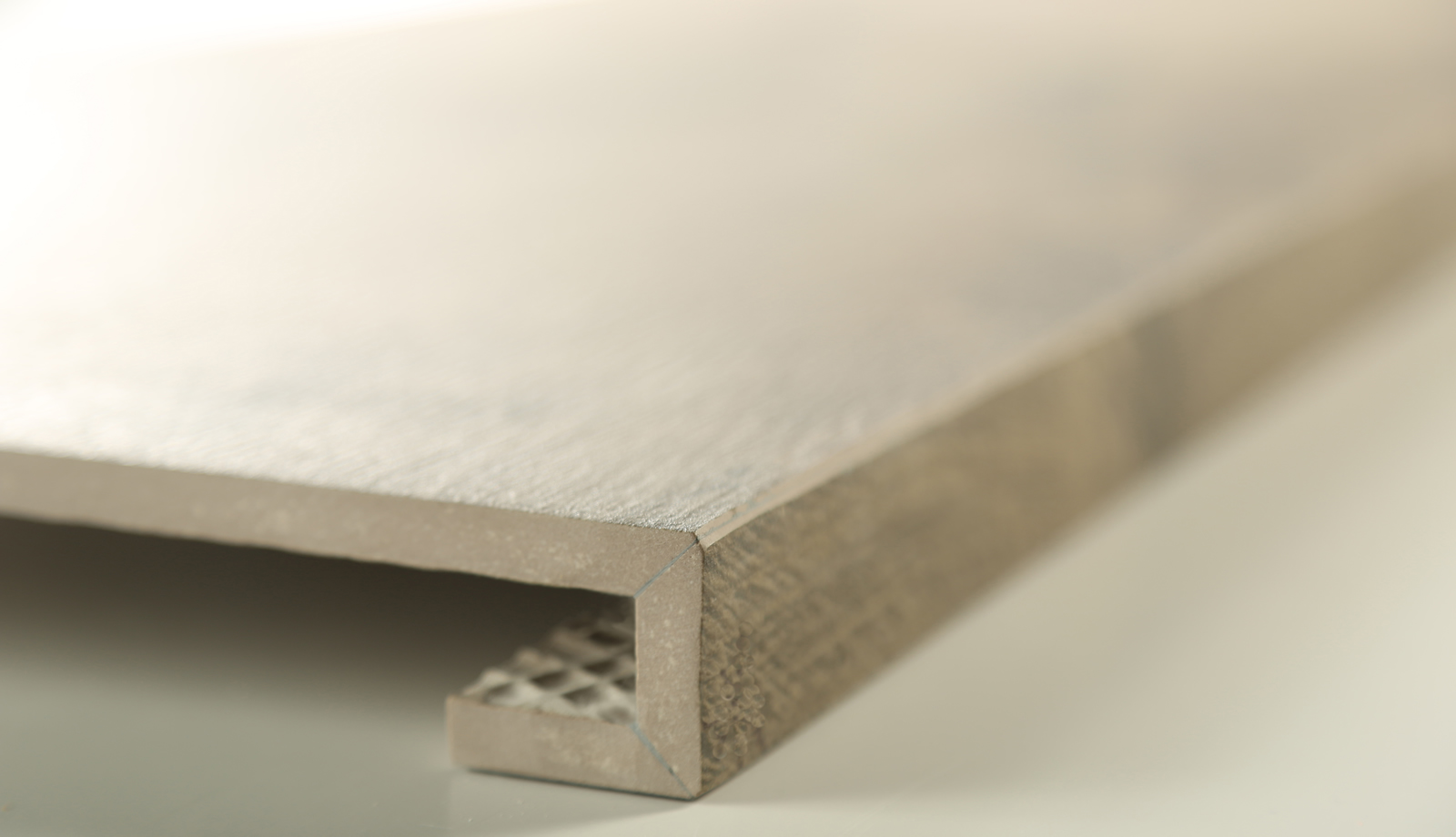

- If the cornice of tread has a cavity - it is filled with the adhesive. Abandoned voids can lead to tile cracking.

- Seams are filled with trowel.

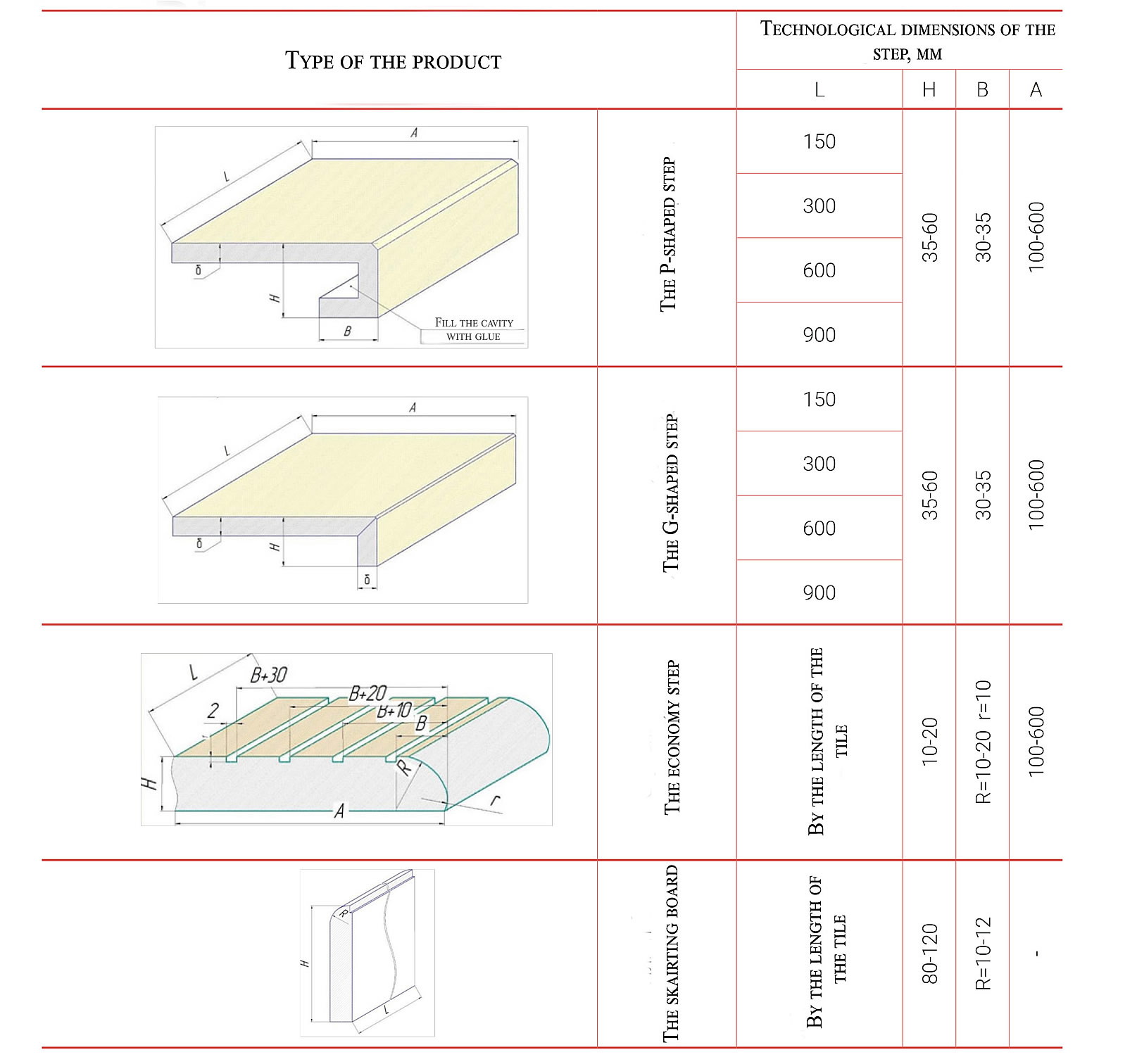

CHARACTERISTICS, TYPES AND SIZES OF PRODUCTS

It is possible to produce steps with different dimensions from those that mentioned in the table, as agreed with the customer.

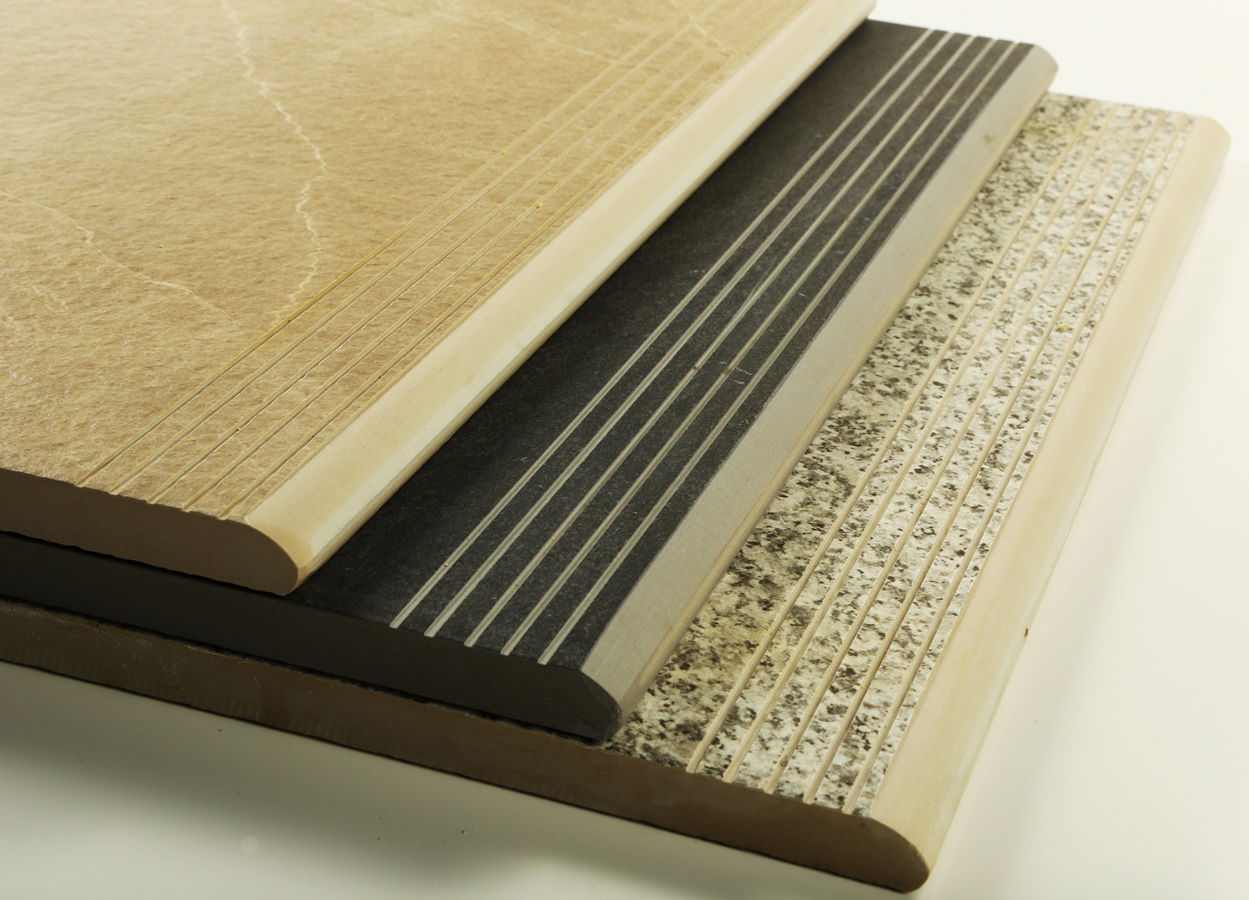

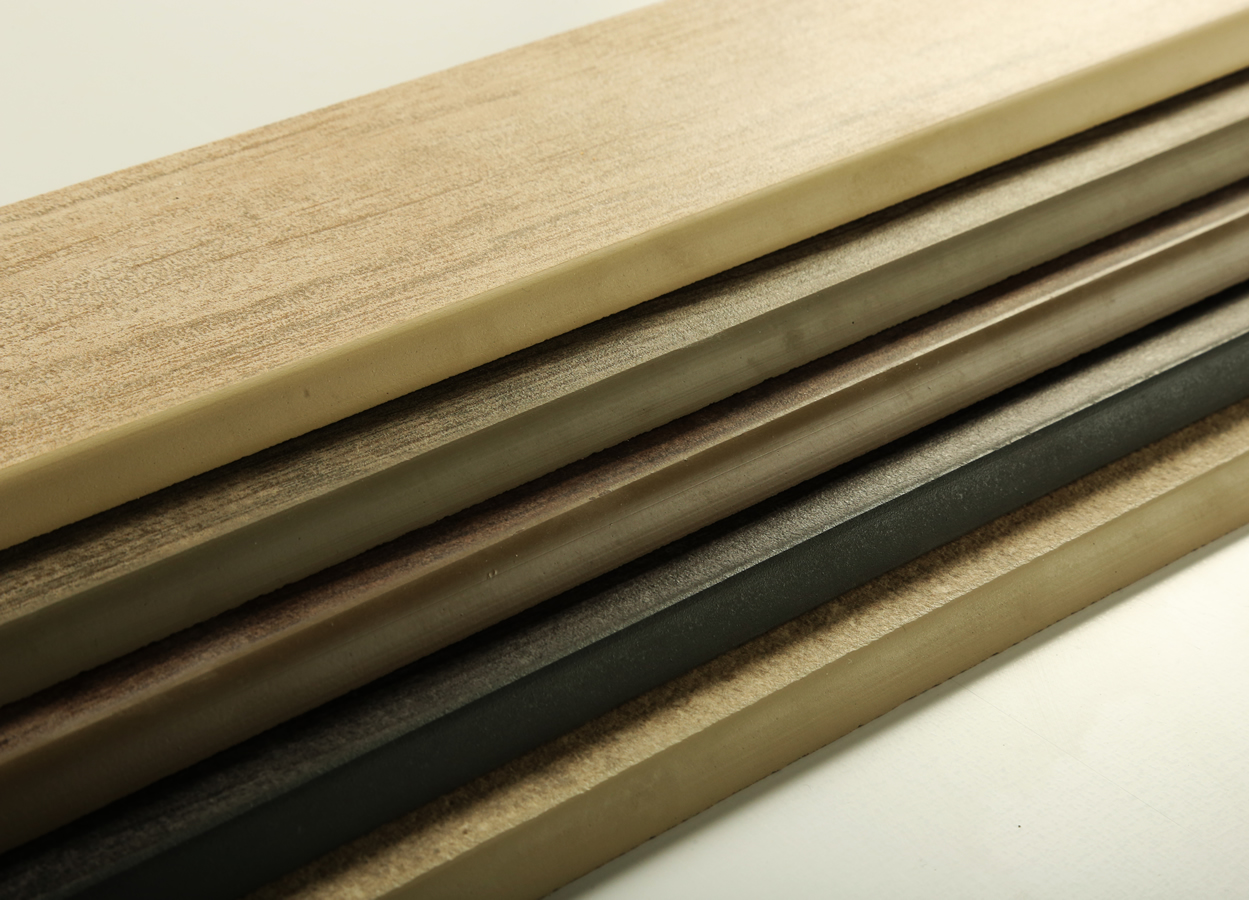

VARIATIONS

Different structures, variety of colors and formats allow to implement any of your projects. It is possible to produce steps with different dimensions from those that mentioned in the table, as agreed with the customer.

To order and skirting boards made of ceramic granite please contact us by e-mail: steps@dcb.com.ua

or by rhe following phone(mentioned below): +38 0626-66-88-55